Production engineering / FA Group, Production Engineering Center

I would like to lead a big project that realizes an ideal production line by fully utilizing state-of-the-art robotics and then introduce the line overseas.

- Y.K.

- He joined the company in 2015. His hobbies are playing tennis, which he started playing when he was in elementary school, and table tennis, which he devoted himself to from junior high to university. In winter he loves snowboarding. As there are many ski hills nearby, his weekends are consumed with snowboarding. His snowboarding skills are definitely improving.

Current Job

Electrical design for automatic assembly machines, robots and tools

My major at university was physics. I like English, too, so I looked for a manufacturer that was expanding business globally and had a corporate philosophy I could share. I visited graduates from my university who were working at different companies and finally I met people at SMK with whom I really wanted to work. I applied for a job at SMK, a global manufacturer with a philosophy I completely understand. My current job is electrical design for automatic assembly machines and tools. I am involved in tasks ranging from wiring to the creation of system control programs. By using particular algorithms we define the operational and functional requirements of the mechanism design engineers, create programs and conduct repeated testing. It is not enough that machines run as required. Our mission is to make machines that stop safely when something goes wrong and restart immediately once a problem is solved.

Job Satisfaction

Delight in seeing a production facility running in accordance with my program

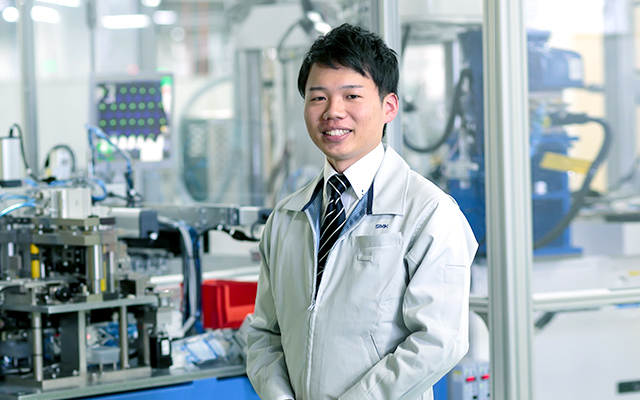

My greatest pleasure is to see a production facility running in accordance with a program I created. When we introduced a full-fledged vertically articulated robot into our production line for the first time at SMK, we created a complicated program to control the robot arms so that it could operate while avoiding obstacles. It was an incredibly difficult project. I will never forget how amazed and impressed everyone was to see the robot moving as we had programmed it to move. Currently several automatic assembly machines and tools that I developed are running on the plant production lines. Whenever I walk into a plant where I can hear sound of the machines operating and producing, my affection for the machines increases and I feel proud of my work. I am always thinking how to improve control systems and SMK's production capability. Getting new ideas one after another increases my motivation for daily tasks.

Challenges and Dreams

To become a robot control systems expert

I would like to gain the knowledge and experience necessary to become a robot control systems expert. In addition to its development and design excellence, SMK's strength is its superior ability to produce high quality products efficiently. The role of the Production Engineering Center is important. Our achievements directly influence SMK's sales and profits. In particular, development and introduction of industrial robots are key to the company's future. This is why I would like to work hard to become a leading expert in robot control systems. My future goal is to utilize state-of-the-art technologies to realize ideal production lines for the plants in Japan and to introduce the same to factories overseas.

Career Step

- 2015 -

-

FA Group, Production Engineering Center

In charge of electrical design for automatic assembly machines and tools