Quality Improvement

Tackling quality improvement

At SMK, we employ an integrated quality management system based on the international standard ISO9001, and the basic concept is Ultimate Quality Management. This involves employees not just from divisions directly involved with production, but throughout the entire company.

SMK aims to achieve Zero Defect (ZD) for quality. We believe that it is only when we are meticulous and enhance the quality of operations at every step—from sales to R&D , design, production, inspection, shipping, and delivery—that product quality arises.

It is particularly important to us not just to address problems during manufacturing, but also to prevent them from occurring through devoted front-loading efforts and DR (Design Review) during the product development stage.

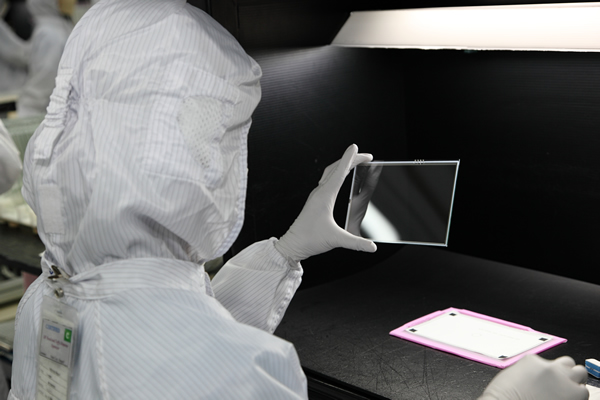

Appearance inspection in the clean room: Philippines

Tackling improvements in customer satisfaction

SMK seeks to make itself a useful presence within society and the first principle of Group Charter for Corporate Behavior is “For customer confidence.” Customer satisfaction is regarded as the most important factor in SMK’s existence and values as a company. And the basis of customer satisfaction lies in the quality of products and sales. All employees including sales people, designers, product engineers, quality engineers, people engaged in production make every effort to quality improvement.

Additionally, members from across our design, production, quality assurance and other divisions come together to discuss rules and guidelines for quality control that must be applied to the whole company.

SMK carries out periodically a customer satisfaction questionnaire to find out how customers view our activities and achievements. We review the results of these surveys throughout the entire company, reflect them in planning for new activities, and aim to achieve even further improvements in customer satisfaction.

Product Design Meetings: U.S.A.

Supply chain management

In making products that SMK provides to our customers, we receive assistance from numerous suppliers. To establish a sustainable supply chain, we ask new suppliers to agree to SMK’s procurement policies and go through appropriate procedures, including on-site process audits, before commencing business.

For existing significant suppliers*, we conduct regular assessments and feedback to maintain a healthy supply chain. Additionally, to ensure the supply of products with stable quality, we hold regular quality meetings with suppliers to monitor quality trends, discuss and provide information for resolving technical issues.

Recognizing the importance of green procurement and CSR procurement in establishing a sustainable supply chain, we are taking the following initiatives:

●Green Procurement:

We promote green procurement by presenting the "Green Procurement Guidelines" and "Controlled Chemical Substances Standard" to all suppliers and procuring materials that meet these standards.

●CSR Procurement:

We present the "SMK Supply Chain CSR Guidelines" to all suppliers and request their understanding of the guidelines and submission of an agreement. For significant suppliers, we aim to obtain a 100% agreement rate.

|

| ||||||

Supply Chain CSR Guidelines ![]() (0.4MB)

(0.4MB)

* Significant suppliers

SMK identifies approximately 200 companies as significant suppliers, focusing on suppliers of raw materials that are important to us and with which we have large transaction amounts.

Monthly Quality Improvement Meetings: Mexico