Environmental Conservation Activities

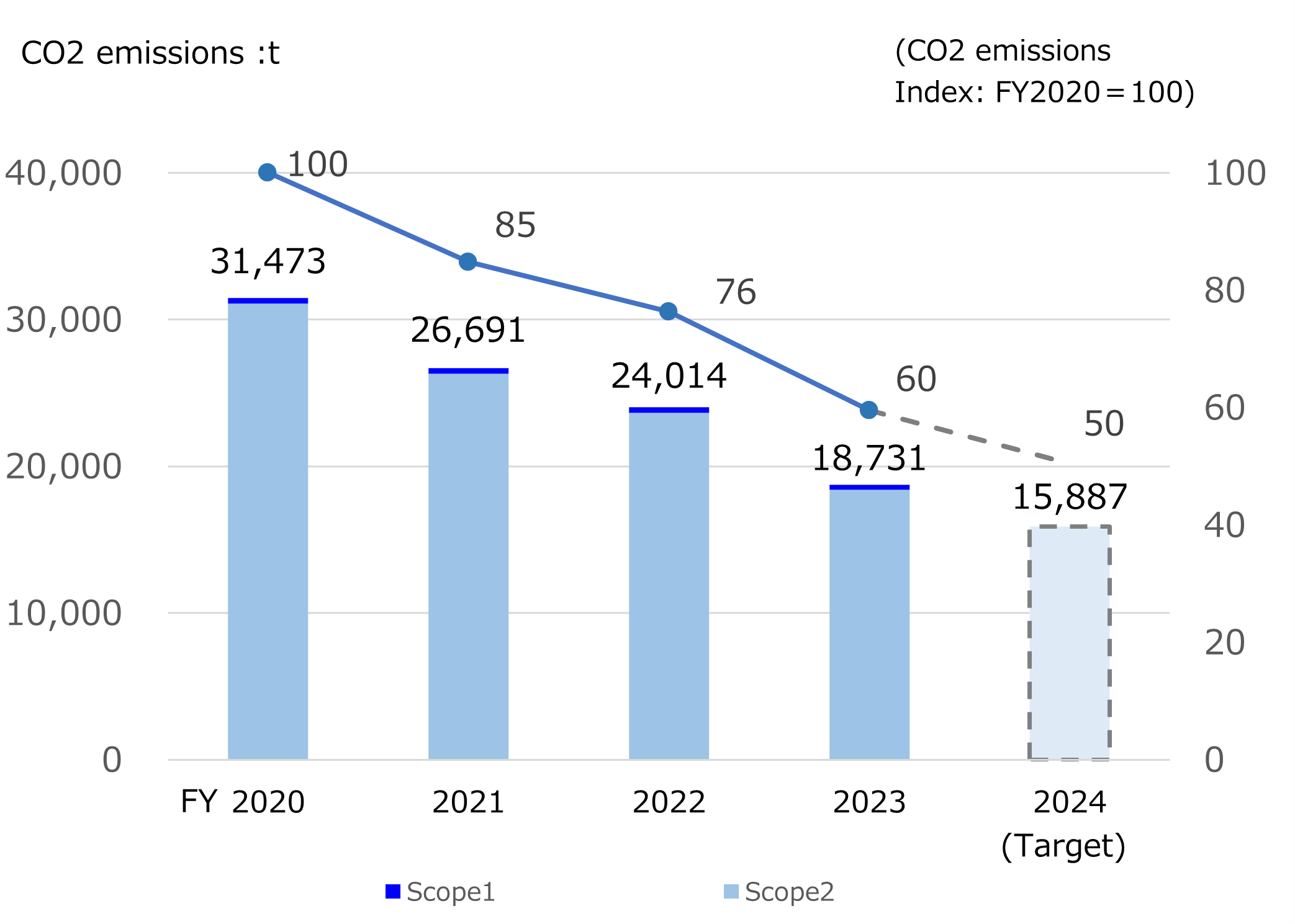

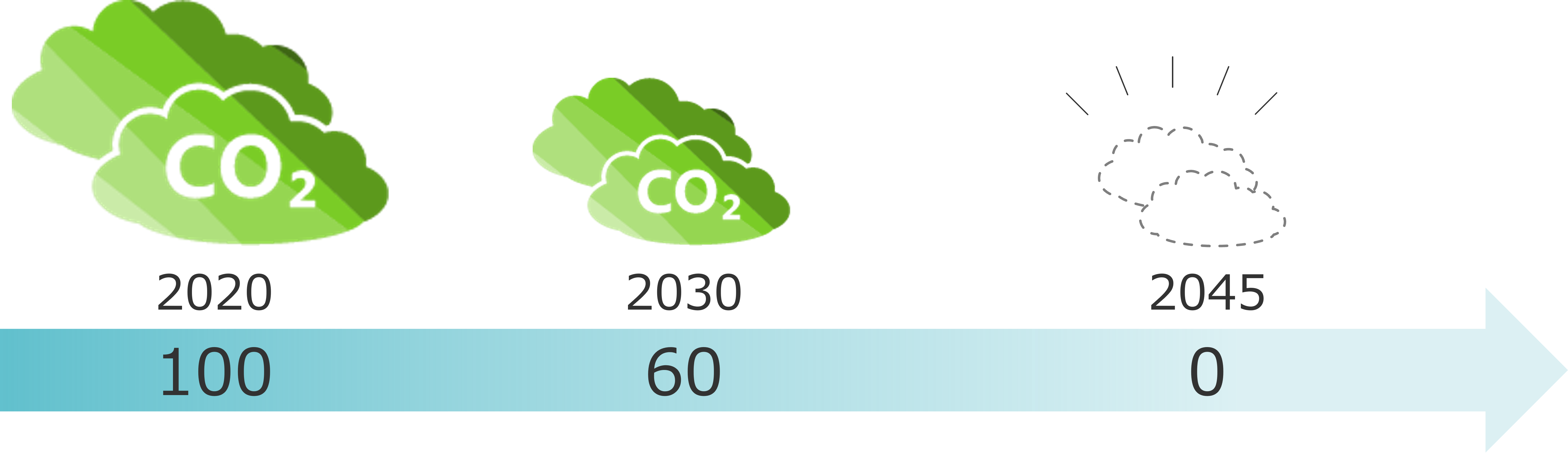

SMK has set medium- and long-term targets for Scope 1 and 2 emissions with the aim of achieving carbon neutrality by FY2045.

In order to ensure the reduction of CO2 emissions even under future business growth, we have changed the management indicator from "per unit of production value" to "Total emissions" from FY2024.

Medium-term Target

FY2030: Reduce CO2 total emissions by 40% from FY2020

Long-term Target

FY2045: Achieve carbon neutrality

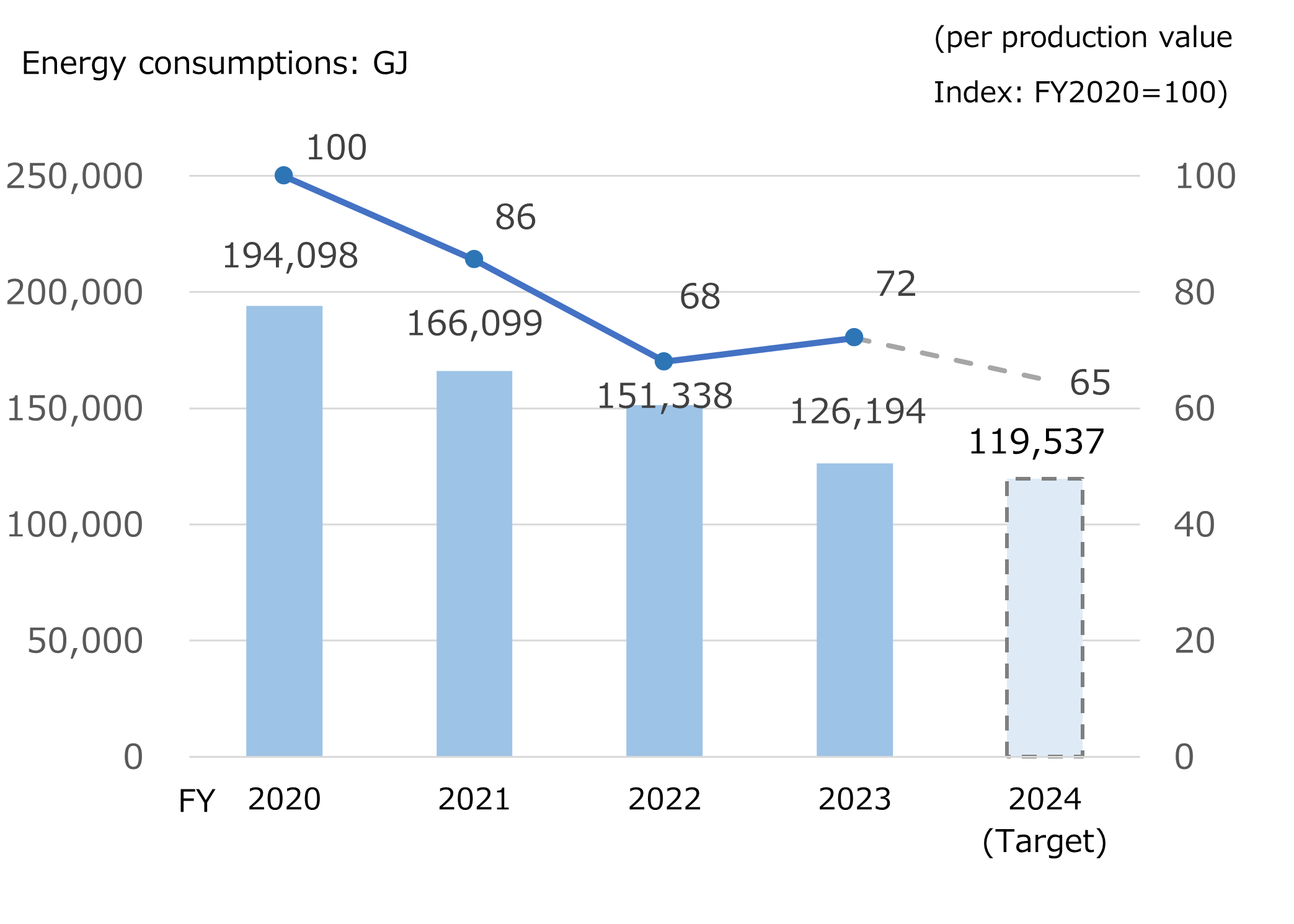

Additionally, SMK is committed to improving energy efficiency in our production processes, aiming for an average annual improvement rate of 1% or more in energy consumption per unit of production value, in line with the Electrical and Electronics Industries' Carbon Neutrality Action Plan.

Key initiatives

● Upgrade to energy-saving facilities

● Expansion of solar power generation equipment

● Consider purchasing certificates or carbon credits

Progress in FY2023

CO2 emissions reduced by 40% from FY2020.

On track to achieve the medium-term target.

FY2023 Environmental Conservation Activities

| Self assessment | |

| A: | Target achieved |

| B: | Target not achieved (improved on the previous year) |

| C: | Target not achieved |

|

|||||||||||||||||||||||||||||||||||||

- *1:Energy consumtions divided by production value

- *2 :CO2 emissions divided by production value

- *3:Waste discharge divided by production value

Energy and Resource Saving Results

Preventing global warming is considered an important management issue, and efforts are being made to improve energy efficiency.

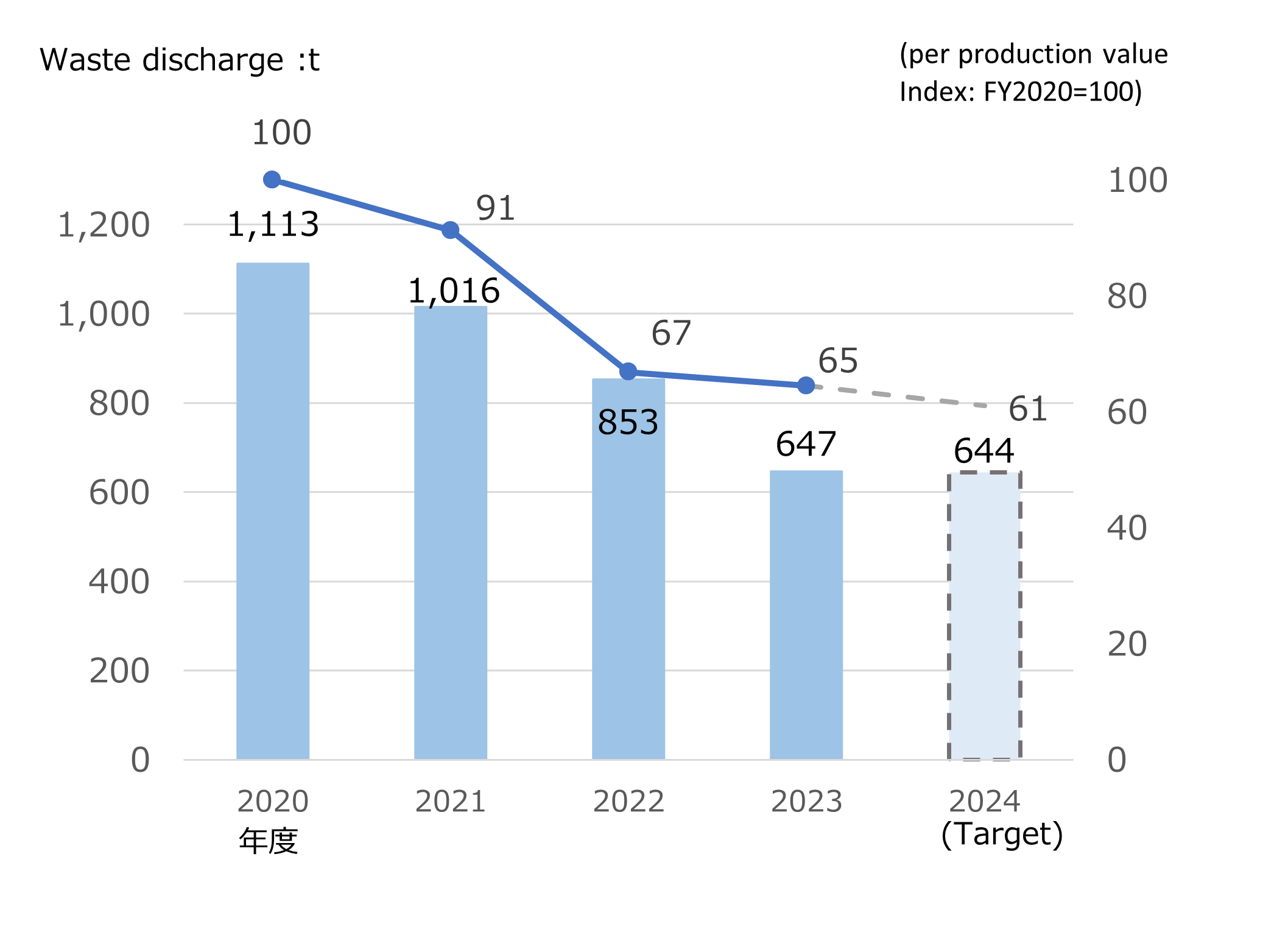

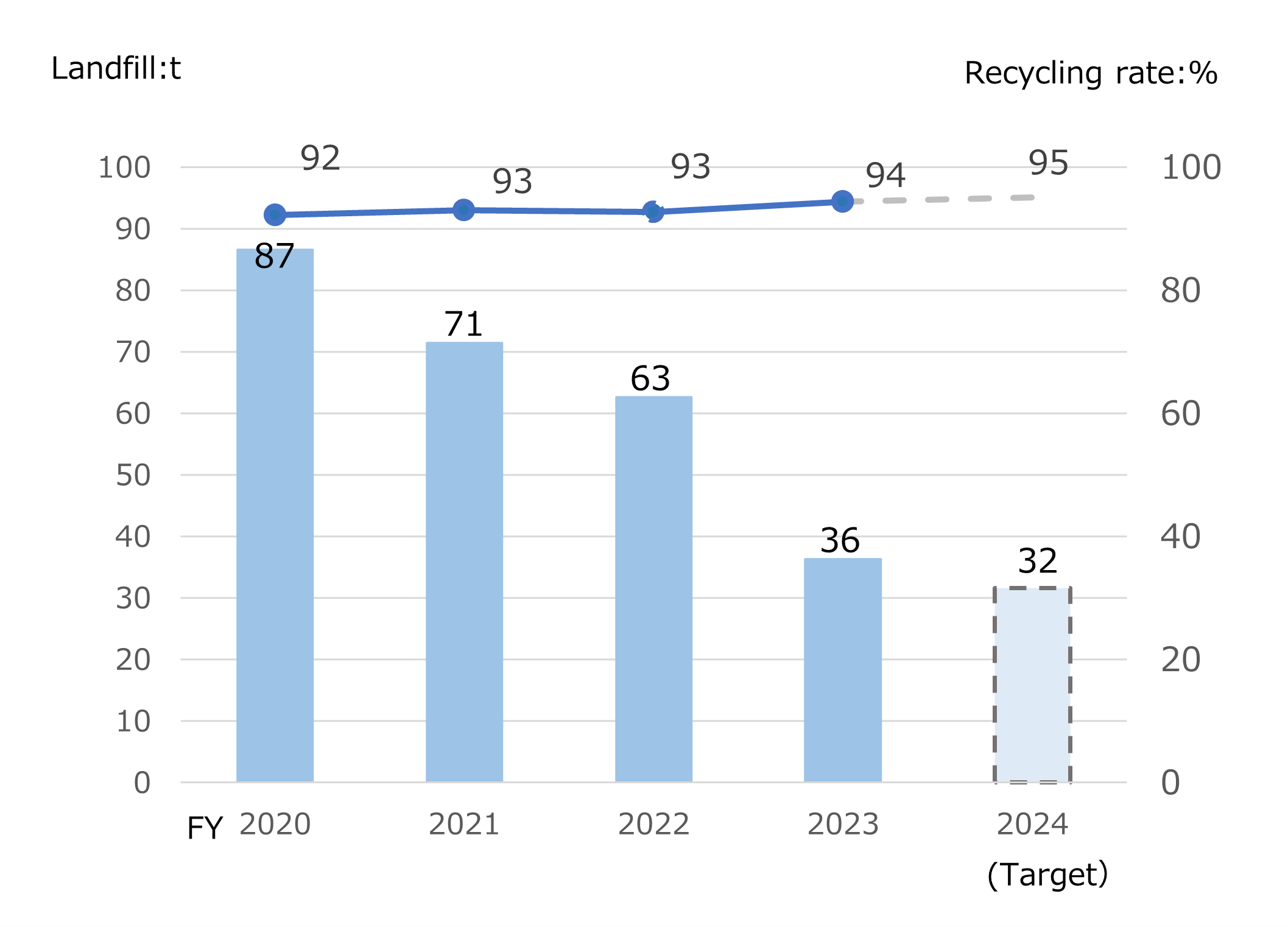

Additionally, initiatives are in place to reduce waste and achieve zero emissions (zero landfill waste disposal), aiming for the effective use of resources.

Energy Saving Results

<Energy consumptions>

- Unit calorific value (fuel) conversion factor:

- ・Factors based on the Ministry of the Environment's "Greenhouse Gas Emissions Calculation, Reporting, and Publication System" are used.

<CO2 emissions>

- CO2 emission factor:

- ・Purchased electricity (Japan) : Factor published by the Electric Power Council for a Low Carbon Society,ELCS are used.

- ・Purchased electricity (Overseas): Factors from IEA Emisson Factor 2021 are used.

- ・Fuel: Factors based on the Ministry of the Environment's "Greenhouse Gas Emissions Calculation, Reporting, and Publication System" are used.

- ・Past results have been revised due to the update of CO2 emission factors.

<Use of renewable energy:>

In FY2023, we promoted the installation of solar power generation facilities at our overseas production sites.

Currently, two sites in Japan and three overseas sites are using solar-generated electricity.

In addition, our China works began purchasing solar-generated electricity in May 2024.

|

|

|

| SMK Philippines | SMK Malaysia | SMK Mexico |

Resource Saving Results

<Waste discharge>

<Landfill waste and recycling rate>

- ・Reporting period: FY2023 (April 1, 2023 – March 31, 2024)

- ・Scope of calculations: SMK Corporation (seven sites in Japan) and consolidated subsidiaries (three in Japan and 16 overseas)

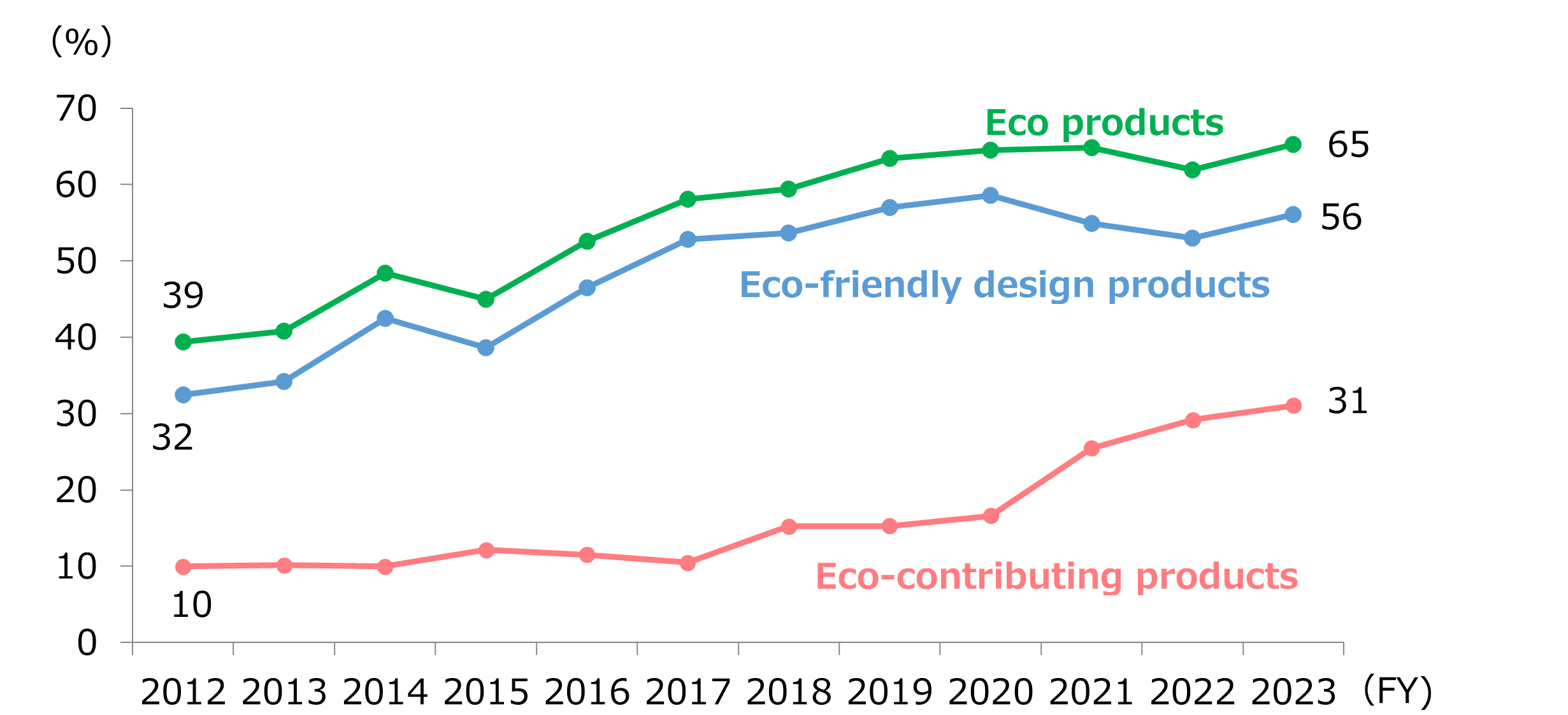

SMK Eco Products

Since fiscal 2012, we have established internal criteria for SMK Eco Products.

Eco products consist of "Eco-contributing products," which are classified by the end market of customer products, and "Eco-friendly design products," which are evaluated based on the level of environmentally friendly design.

| ||||||||

Percentage of sales of Eco Products

*SMK Eco products =Eco-contributing products plus Eco-friendly design products

(If both are applicable, they will be counted unduplicated.)