UL recognized “photovoltaic cell module connector”for photovoltaic power generation systems marketed

We are pleased to announce that we have earned recognition from UL for the American market for our “photovoltaic cell module connector” which has been accepted in the photovoltaic power generation system market very favorably. Specifics of this connector are given below.

Generation systems of photovoltaic power, a clean energy, have drawn attention and demands have grown centering around in Europe, and also in the USA, where growth of the presence of this system is expected. Photovoltaic generation systems comprise multiple photovoltaic cell modules connected with cables and are installed on rooftops. For connection of cables, relay connectors are used. These connectors are installed outdoors, so they are required to be waterproof and resistant to weather. Workability during installation is also important.

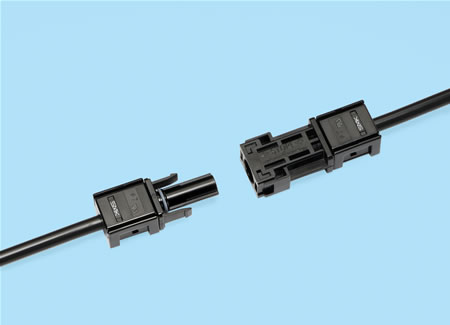

This connector is designed to relay cables emerging from photovoltaic cell modules. Under such circumstances and with our eyes focused on the big potential for further expansion lying in this market, we developed the “photovoltaic cell module connector” excellent in contact performance, waterproofing property and workability, and recently earned UL recognition.

In addition to TUV certification for European markets, we have also acquired UL recognition, which will enable us to evolve and spread marketing activities in the North American market.

| Date Released | Jan. 29, 2009 | |

|---|---|---|

| Press Release No. | 848cs | |

| Product Name | Photovoltaic cell module connector | |

| Drawing Nos. | Plug: CCT9901-18□□F Socket: CCT9901-19□□F | |

| Features | 1) Excellent contact performance is a reality with our proprietary multi-point contact system. (Patent pending) 2) Easier and tool-free application of waterproofing property around cables is possible due to our exclusive waterproofing structure (top and bottom cover system) for excellence in waterproofing performance and workability. (Patent pending) 3) A locking mechanism is featured. The locking section cannot be manually undone. (Patent pending) 4) Capable of handling a large current. 5) A copper alloy spring material is used for superb electrical conductivity. 6) A plastic material with excellent weatherability and flame retardancy (UL94V-0) is used. 7) UL recognized. 8) TÜV certified. 9) RoHS Directive compliant. | |

| Major specifications | Voltage and Current Rating | 30A, 1000V [TUV spec.] |

|---|---|---|

| 28A, 600V (AWG12 wire) or | ||

| 25A, 600V (AWG14 wire) [UL spec.] | ||

| Operating Temperature Range | -40℃ to +90℃ | |

| IP Protection Class | IP 67 / IP 2X (when disengaged) | |

| Applications | Photovoltaic power generation systems | |

| Production capacity | 500,000 units/month | |

| Inquiry | * For more information, please contact the CS Division Fax : 81-3-3785-0517 | |

- April, 2025 ~ March, 2026

- April, 2024 ~ March, 2025

- April, 2023 ~ March, 2024

- April, 2022 ~ March, 2023

- April, 2021 ~ March, 2022

- April, 2020 ~ March, 2021

- April, 2019 ~ March, 2019

- April, 2018 ~ March, 2019

- April, 2017 ~ March, 2018

- April, 2016 ~ March, 2017

- April, 2015 ~ March, 2016

- April, 2014 ~ March, 2015

- April, 2013 ~ March, 2014

- April, 2012 ~ March, 2013

- April, 2011 ~ March, 2012

- April, 2010 ~ March, 2011

- April, 2009 ~ March, 2010

- April, 2008 ~ March, 2009

- April, 2007 ~ March, 2008

- April, 2006 ~ March, 2007